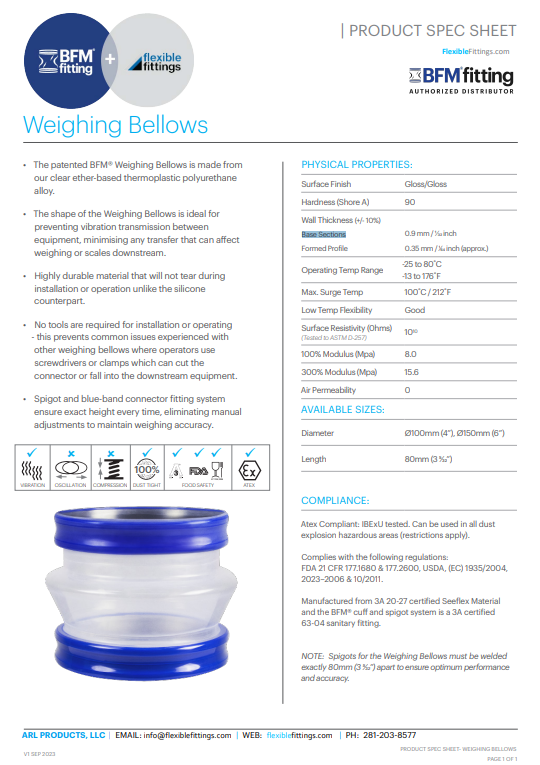

BFM® connector designed for loss-in-weight & dosing applications

The BFM® Weighing Bellows is designed to minimize resistance transfer on weighing equipment.

Made from our super strong but flexible urethane-based Seeflex 040E material, the BFM® Weighing Bellows won't fracture as a result of constant flexing.

Snap-fit connector & spigot design ensures fast, accurate installation every time connector is removed & replaced.

Designed for applications where precise weighing is required.

| Physical Properties | |

|---|---|

| Surface Finish: | Gloss/Gloss |

| Hardness (Shore A): | 90 |

| Wall Thickness (+/- 10%) | 0.9 mm / 1/32 inch |

| Tensile Strength (MPa) | 40 |

| Operating Temp Range | -25 to 80°C |

| Max Surge Temp | 100°C / 212°F |

| Low Temp. Flexibility | Good |

| Surface Resistivity (0hms) (Tested to ASTM D-257) | 1010 |

| 100% Modulus (MPa) | 8.0 |

| 300% Modulas (MPa) | 15.6 |

| Air Permeability | 0 |

| Dimensions | Diameters: Ø100mm (4"), Ø150mm (6") Length: 80mm (3") |

Accurate installation of BFM® spigots is a critical step in ensuring the BFM® Weighing Bellows functions as designed.

Video Transcript

Installing your BFM Spigots for Weighing Bellows:

Having the correct installation gap (IG) is extremely important for optimal performance.

Spigots for Weighing Bellows must be installed exactly 80mm (3 5/32") apart.

All Weighing Bellows connectors are the same height and the installation gap must be 80mm (3 5/32") for optimal performance.

Top & bottom spigots must be aligned vertically with no offset.

What is the BFM® Weighing Bellows?

Watch this video to hear from a BFM® expert explaining why the BFM® Bellows is an ideal connector for loss-in-weight applications.