90% saving on cleaning costs alone [Food Processing]

Chris Clifford, Site Maintenance Manager, Berryville:

“BFM® fittings are saving us around $225,000 a year in cleaning costs alone!”

One of the world’s largest processors of chicken meat, Tyson Foods Inc., supplies chicken products to some of the biggest retail food chains in the country, including KFC, McDonald’s, Burger King, Wendy’s and Wal-Mart.

Strict hygiene laws require the entire plant’s machinery to be stripped down and thoroughly cleaned and after a maximum of 12 hours’ operation. The traditional hose-clamp connectors not only leaked, they were extremely difficult to remove and replace correctly during each cleaning cycle - then they discovered BFM® fitting and are making significant savings!

BEFORE BFM

The chicken meat is transported around the production plant via vacuum pump in a 'slurry' form to be processed into various chicken products.

The existing hose-clamps were difficult to remove and replace and they leaked - posing an additional health risk. The vacuum running through the system was also compromised by the leakage, reducing efficiency throughout the plant.

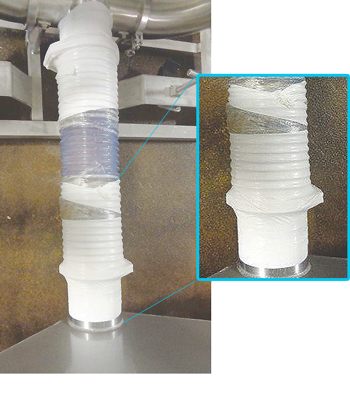

Staff had resorted to applying tape to the outside of the hose-clamped connectors to try and stop this leakage, which added to the complexity of removing and replacing connectors at each cleaning changeover.

This messy, time consuming removal and reinstallation process was extremely labor intensive, and the variety of connector sizes throughout the plant also made for complex inventory control.

AFTER BFM

Three initial BFM® fittings were installed as a trial at the Berryville Plant in Arkansas. Much of the plant equipment is installed on wheels to allow easy access for cleaning, so to prevent the pipes being pulled together under vacuum, a simple clamp system was installed over each BFM® fitting, still allowing full access to remove the connectors.

The ‘snap-fit’ simplicity of removing and replacing the connectors vs the hose-clips and tape has enabled Tyson's maintenance team to reduce their cleaning changeover labour costs from $250,000 pa to around $25,000pa - a 90% saving!

In addition, the 100% seal means the vacuum transportation system runs much more effectively at a higher pressure, increasing overall production efficiency.

They have also managed to standardise all flexible connectors in the plant down to five types - simplifying inventory management.

The Benefits of BFM® fitting

![]() HYGIENE: The 100% seal has eliminated risk of leakage of any raw chicken slurry and has made the entire cleaning and replacement process simple and hygienic.

HYGIENE: The 100% seal has eliminated risk of leakage of any raw chicken slurry and has made the entire cleaning and replacement process simple and hygienic.

![]() DOWNTIME: Connector removal and replacement time is much faster, reducing labour significantly and saving Tyson foods $225,000 per year in cleaning costs alone.

DOWNTIME: Connector removal and replacement time is much faster, reducing labour significantly and saving Tyson foods $225,000 per year in cleaning costs alone.

![]() INSTALLATION: The custom BFM® top and bottom spigots means the connector can now easily be snap-fitted back into position - and is always fitted correctly.

INSTALLATION: The custom BFM® top and bottom spigots means the connector can now easily be snap-fitted back into position - and is always fitted correctly.

![]() STANDARDISATION: By installing BFM® fitting, Tyson Foods have managed to standardize all of their flexible connectors to five different types, helping manage their inventory.

STANDARDISATION: By installing BFM® fitting, Tyson Foods have managed to standardize all of their flexible connectors to five different types, helping manage their inventory.

The BFM® fittings have made the dismantling and reinstallation process so much faster than before saving us a massive amount of downtime. The simple snap-fit connectors mean they are always installed correctly in exactly the right position in a fraction of the time it used to take. The system is also now 100% sealed during both the processing and cleaning operations which means the whole plant is much cleaner and runs more efficiently.

- Chris Clifford, Site Maintenance Manager, Tyson Foods Berryville.

Watch BFM® fitting in action

Have you checked out the BFM® IG calculator?

The biggest single cause of product 'failure' for BFM® fitting is an incorrect Installation Gap - ie. the space left between the spigots is either too big or too small for the connector chosen.

Understanding the correct IG is easy with the BFM® IG Calculator. Check it out here.

Have an application question?

Ask Baxter!

Meet our resident expert on all things BFM®. Shoot us an email, get us on web chat, or call us right now. Professor Baxter is here to answer all your questions.

FOOD MANUFACTURERS USING BFM® FITTING

![]()