The perfect solution - BFM® fitting for Dairy

Certified for use in USDA and 3-A powder applications

HYGIENE: No dust leakage

- 100% sealed

- Eliminate dust leakage

- Eliminate cross-contamination of products.

EASY INSTALL: No tools

- Snap-fit installation

- Change-overs in minutes

REDUCED DOWNTIME: Clean in Place

- Fast and efficient cleaning in between product runs

- Spend less time cleaning & maintain the highest sanitary standards

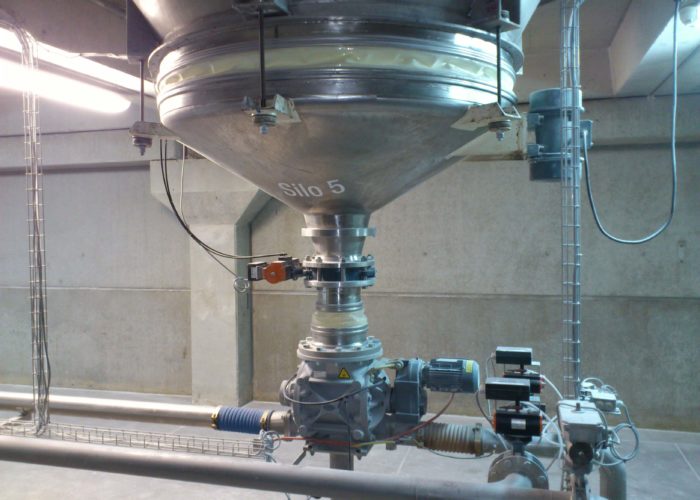

BEFORE BFM

The regular gas purging of the system forced powder through small gaps in the old-style sock and steel clamp connector.

This caused an unhygienic environment and hours of down-time for regular cleaning. There was also a major contamination point created by significant product build up between the externally fitted sock and hopper.

The steel strapping clamps were very time consuming to remove and re-fit during sock cleaning & replacement.

AFTER BFM

The installation of a BFM® fitting sanitary connector for both the upper and lower connections has created a sealed system, and the filling room is now a dust-free environment.

The pressure from the gas purging no longer causes product leakage, and because the fitting sits inside the spigot, there is no product build-up at the connector joins.

When the fittings do need replacing, it’s now a quick and easy snap-fit process.

Since installing the BFM® fitting sanitary connector system, the room is clean and there has been a significant reduction in both downtime and replacement costs.

Need to customize your BFM® spigot? ARL Products can help.

Check out this bad boy! BFM fitting 316SS spigot reduced to tri clamp fitting and electropolished to Pharmaceutical / Nutraceutical grade.

With free in-house engineering, custom fabrication abilities, and large inventory, ARL Products makes it easy to design and retrofit BFM® fitting sanitary connector systems in your facility.

BFM® fitting in dairy

Have you checked out the BFM® IG calculator?

The biggest single cause of product 'failure' for BFM® fitting is an incorrect Installation Gap - ie. the space left between the spigots is either too big or too small for the connector chosen.

Understanding the correct IG is easy with the BFM® IG Calculator. Check it out here.

Have an application question?

Ask Baxter!

Meet our resident expert on all things BFM®. Shoot us an email, get us on web chat, or call us right now. Professor Baxter is here to answer all your questions.

FOOD MANUFACTURERS USING BFM® FITTING

![]()